Digital Measurement

Precision that powers production—across every industry.

What We Offer

At Digital Measurement Services, our mission is to offer exceptional digital measurement solutions customized to our clients requirements. Whether it is precise measurements for manufacturing or detailed CAD files, we excel in delivering dependable services that meet production standards seamlessly

- Kitchen

- Vanity

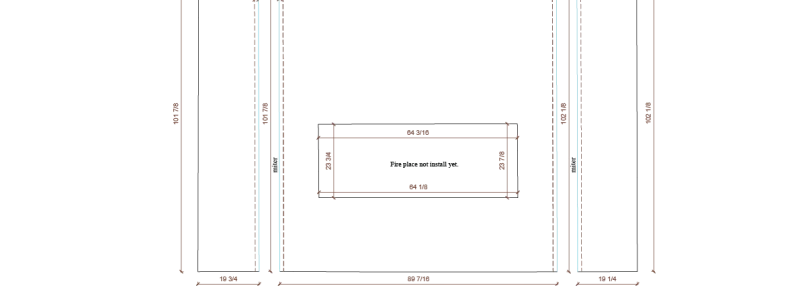

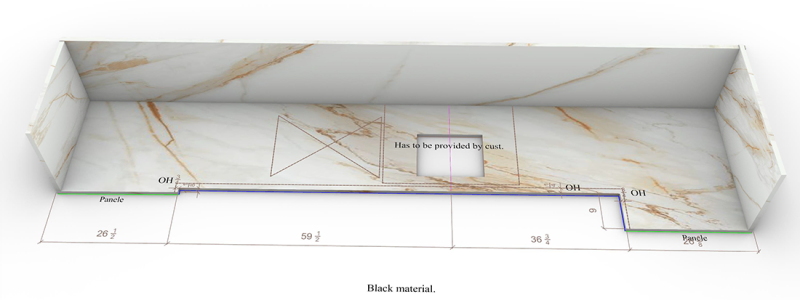

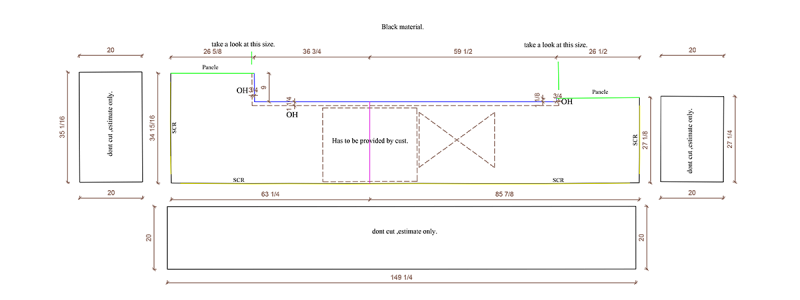

- Fireplace

- Full Height Backlash

- Tub Sorrounding

- Mill Work

- Mitter Jobs

- Shower Encloser

Stone Industry

From residential kitchens to large-scale commercial installations, our digital templating ensures flawless fits for all stone applications. We capture every curve, cutout, and edge with millimeter precision.

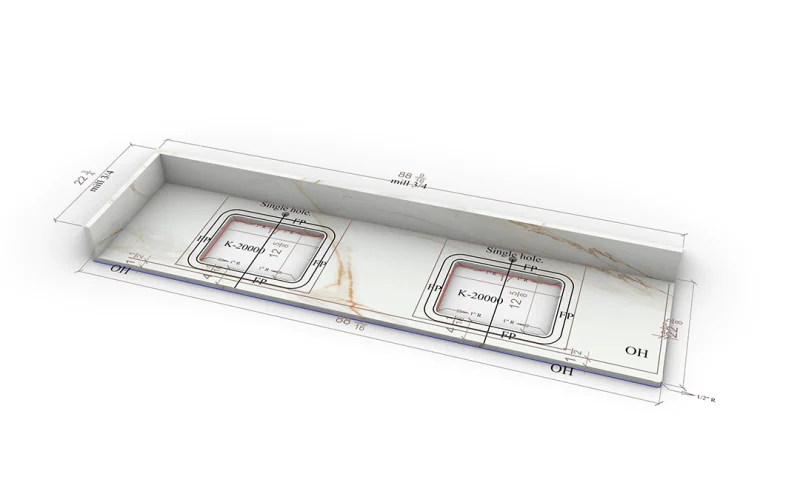

- Kitchen Countertops – Sink cutouts, appliance clearances, and edge profiles measured for seamless fabrication.

- Bathroom Vanities – Includes sink placement, faucet holes, and backsplash transitions.

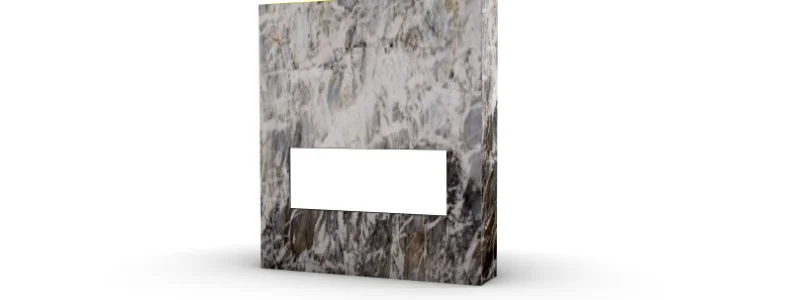

- Fireplaces – Templates that follow unique hearths, mantels, and full-wall cladding.

- Bathtub Surrounds – Measure around curves, niches, and multi-surface transitions with zero guesswork.

Kitchen

Vanity

Fireplace

Pantry

Doors and Windows

Glass elements require absolute accuracy—whether structural or decorative. We deliver reliable measurements for custom fabrication.

- Windows – Full-frame scans for retrofit or custom-sized panels.

- Doors – Precise cutouts and hinges for glass doors, frameless showers, and partitions.

Furniture

Custom cabinetry and furniture components need exact dimensions—especially in tight, fitted spaces. We provide clean files for CNC or manual fabrication.

- Tables – Templates for unique shapes, overhangs, or integrated lighting.

- Cabinets – Precise exterior and cutout dimensions for built-ins and custom boxes.

- Desks – Accurate layouts including cord channels, risers, and edges.

Marine

Boats are full of irregular angles and tight curves. Our marine measurement service adapts to complex surfaces with exceptional precision.

- Boat Decks – Template entire decks, hatches, and seating areas to match curved and uneven geometry.

- Boat Interiors – Wall panels, cabinet layouts, and hardware locations captured in 3D or 2D.

- Cabins – Fully mapped layouts for headliners, galley counters, and storage.

Automotive

We support automotive interior customization with exact-fit templates for custom panels, upholstery, or inlays.

- Interiors – Measure dashboards, center consoles, trim kits, and liners with precision.

Step-by-Step Process

We’ve refined our digital templating workflow to ensure every measurement is accurate, on time, and production-ready from the start.

1. Project Intake & Prep

Receive basic project info: scope, surfaces, materials, site address

Review cabinet layouts, sink models, edge profiles, or site photos

Confirm timeline and special requests (e.g., CNC-ready output, 3D rendering)

2. On-Site Measurement

Technician arrives with Proliner, LT-2D3D, or LiDAR scanner

Captures all dimensions, cutouts, wall angles, and context photos

Average job time: 30–90 minutes depending on complexity

3. Data Validation & Cross-Check

Review raw data against plans or client input

Resolve any discrepancies or missing information before file generation

For complex jobs, generate preview layouts for review

4. File Generation & Documentation

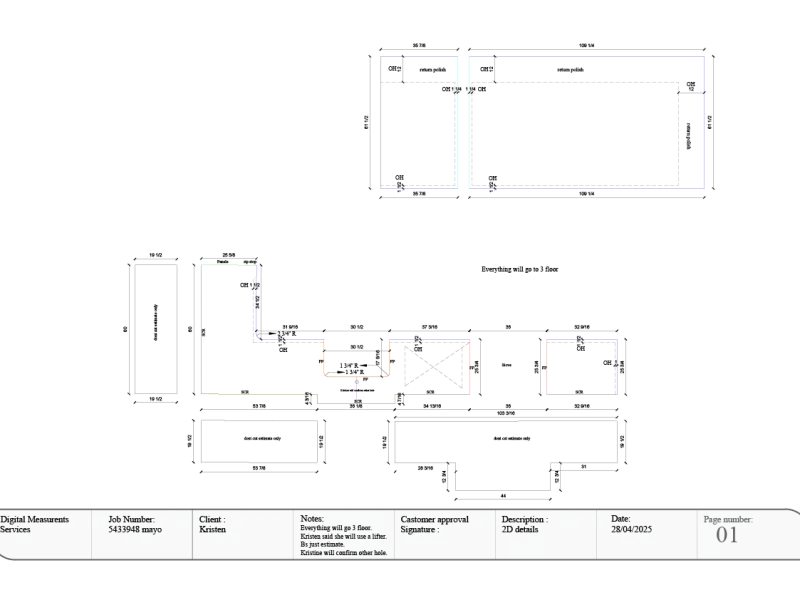

Produce DXF (CNC-ready), PDF (scaled layout), and high-res site photos

Include labeled cutouts, sink drops, notches, and transitions

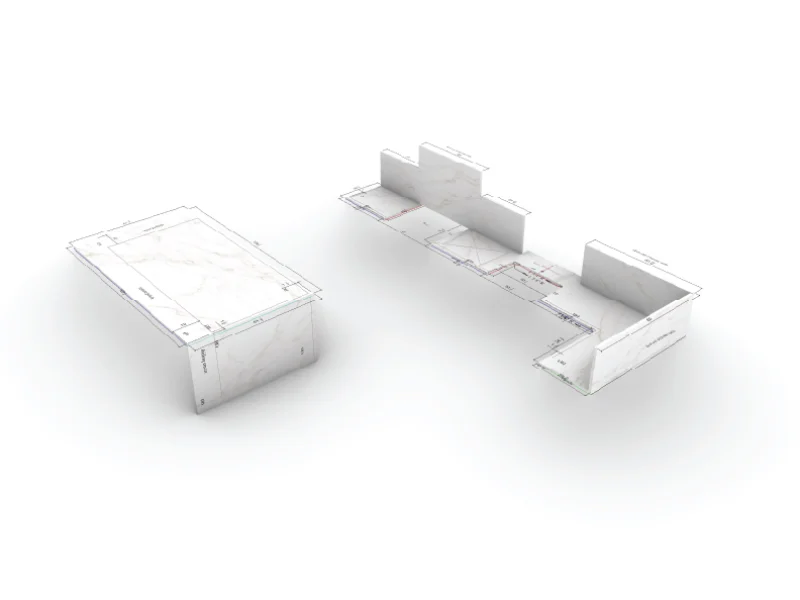

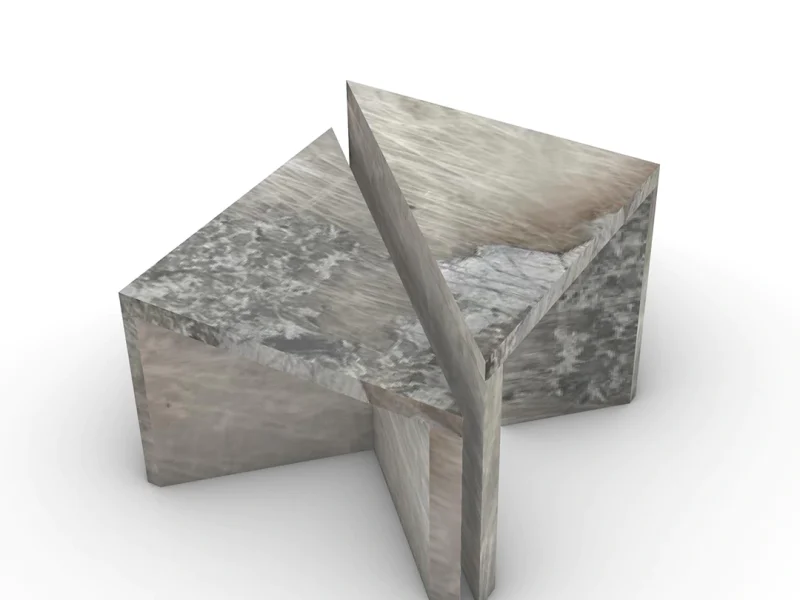

Optional: 3D models or renderings added for advanced visualization

5. Client Review & Approval

Send deliverables via email or client portal

Digital sign-off collected to confirm layout before fabrication

72-hour free revision window for minor edits

6. Final Delivery

Files packaged and delivered to fabricator or design team

Add-ons like layout sheets or blueprint overlays delivered as needed

Optional: coordination with installers for precision fit

- DXF File: Optimized for CNC machines or manual cutting — includes labeled sections, cutouts, and radius data.

- PDF Layouts: Scaled 1:1 drawings for visual verification and manual review on-site or in-shop.

- Site Photos: High-resolution images showing surrounding walls, obstacles, plumbing, and mounting conditions.

- Cutout Details: Precise dimensions for sinks, faucets, outlets, overhangs, miters, and complex notches.

- Customer Signature Sheet: Verified and signed layout approval to eliminate fabrication liability and change orders.

- Optional 3D Models: Full surround assembly for visualization and approval.

- Delivery within 24–48 hours after on-site capture

- Includes all base deliverables: DXF, PDF, photos, approval sheet

- 12-hour express delivery available upon request

- Ideal for urgent installations, tight production windows, or same-week fabrication

- Standard residential surface (e.g., countertop, vanity, table)

- Complex/multi-surface projects

- 3D renderings or CNC-optimized layouts: custom quote

Frequently Asked Questions

Yes. All base structures must be installed, level, and secure before we begin measuring. This ensures accurate cutouts and alignment.

Most jobs take between 30 and 90 minutes, depending on size and complexity.

You’ll receive DXF and PDF files, along with site photos. Optional 3D models and CNC-optimized DXFs are available on request.

Absolutely. Minor adjustments within 72 hours are included. Larger revisions may incur a small fee.

Yes. Our Proliner and LT-2D3D scanners are designed to handle complex shapes with millimeter precision.

Yes. We serve the stone, glass, furniture, marine, and automotive industries. See our full services list or contact us for tailored solutions.

Use our online Google Calendar booking link or call us directly. We’ll confirm availability and walk you through the prep.

Case Study